Polyurethane System Improvements

DESIGNED BY: Young Solutions Inc.

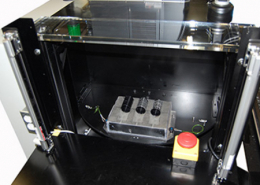

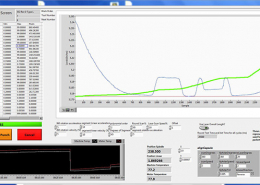

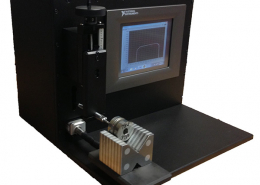

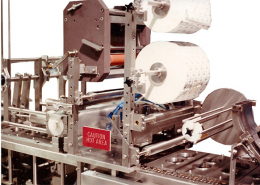

This customer had been utilizing techniques and equipment that were originally developed during the infancy of their production process. The process was hampered by a variety of constraints that caused excessive scrap and lost production. These limitations included: improper hydraulics, thermodynamic limitations, material selections which were not compatible with the process, and a lack of user friendly controls. The new system incorporated numerous improvements including:

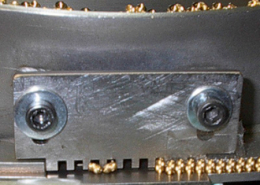

- Chemically inert stainless piping and components

- Hydraulic design considering flow rates, head pressures, and viscosity

- Low wattage warming system and controls for highly viscous materials

- Sight glasses providing an hours advance notice for tote changes

- Quick connectors with drip trays to reduce mess

The scrap reduction alone from these systems created a payback of about one month, and saved the company over $500,000.00 annually.